View the offerings and schedules below to learn more about our sheet metal fabrication machine training courses. Register for one of the upcoming Salvagnini training courses at our technical training center in Ohio.

salvagnini

Training Class Schedule and Descriptions

The Classes

Click into each of the Salvagnini training classes below for more information, and then view the calendar for the next upcoming class.

Operator or Technical* Training & Preventative Maintenance

*SYSTEM SPECIFIC

TRAINING CALENDAR 2023

| COURSE NAME | LOCATION | COURSE DATES | SEATS AVAILABLE | REGISTER |

|---|---|---|---|---|

| TECHNICAL AND PREVENTATIVE MAINTENANCE | Hamilton OH | 21 MAR - 23 MAR | 4 OUT OF 6 | CLOSED |

| STREAMLASER PROGRAMMING | Hamilton OH | 28 MAR - 31 MAR | 6 OUT OF 8 | CLOSED |

| STREAMBEND PROGRAMMING | Hamilton OH | 27 MAR - 31 MAR | 5 OUT OF 8 | CLOSED |

| STREAMBEND PROGRAMMING | MEXICO OFFICE | 27 MAR - 31 MAR | 4 OUT OF 4 | FULL |

| STREAMBEND PROGRAMMING | Hamilton OH | 10 APR - 14 APR | 2 OUT OF 8 | CLOSED |

| STREAMPUNCH PROGRAMMING | Hamilton OH | 10 APR - 14 APR | 5 OUT OF 8 | CLOSED |

| STREAMBEND PROGRAMMING | Hamilton OH | 17 APR - 21 APR | 1 OUT OF 8 | REGISTER NOW |

| STREAMBEND PROGRAMMING | ONLINE | 24 APR - 28 APR | 8 OUT OF 8 | REGISTER NOW |

| STREAMLASER PROGRAMMING | Hamilton OH | 25 APR - 28 APR | 6 OUT OF 8 | REGISTER NOW |

| TECHNICAL AND PREVENTATIVE MAINTENANCE | Hamilton OH | 2 MAY - 4 MAY | 6 OUT OF 6 | CLOSED |

| STREAMPUNCH PROGRAMMING | Hamilton OH | 8 MAY - 12 MAY | 4 OUT OF 8 | REGISTER NOW |

| STREAMBEND PROGRAMMING | Hamilton OH | 8 MAY - 12 MAY | 4 OUT OF 8 | REGISTER NOW |

| STREAMBEND PROGRAMMING | Hamilton OH | 15 MAY - 19 MAY | 4 OUT OF 8 | REGISTER NOW |

| STREAMLASER PROGRAMMING | Hamilton OH | 16 MAY - 19 MAY | 8 OUT OF 8 | CLOSED |

| STREAMBEND PROGRAMMING | Hamilton OH | 22 MAY - 26 MAY | 4 OUT OF 8 | REGISTER NOW |

| STREAMFORMER PROGRAMMING | Hamilton OH | 24 MAY - 26 MAY | 4 OUT OF 4 | CLOSED |

| STREAMPUNCH PROGRAMMING | Hamilton OH | 22 MAY - 26 MAY | 8 OUT OF 8 | CLOSED |

Operator

or Technical*

Training and Preventative Maintenance

*system specific

-

Operator Training and Preventative Maintenance

This course is intended for the person who will run the system in a production capacity.

The course will cover every aspect of running production. It will begin with the Human Machine Interface (HMI) that pertains to that system, and how to navigate all of the menus and features of the software.

Training available on:

• Salvagnini FACE

• Salvagnini Console

• Syscon Shell

All the information needed to correctly load material into the system is explained with practical exercises. Loading and fine tuning a program is also an important lesson.

Then running production in the different modes available is covered in detail. It is also important to understand the messages an operator will see during production and otherwise. This includes all of the manual commands that are available along with any peripheral components.

Finally, the course will show how to deal with common scenarios and unloading the produced parts or panels.

The next part of the course will focus on the preventative maintenance list of the specific system. We will incorporate the use of the on-board Maintenance Manager application that will aid in keeping track of maintenance items.

The Preventative Maintenance chapter will be utilized along with guiding the worker to the indicated point on the system for each item.

This course is limited to one system per course. Make sure to insert the intended system when registering.

This course is available on-site at your facility or in our Hamilton, Ohio Salvagnini America Campus.

Course Length: 3 days

-

Technical Training and Preventative Maintenance (System specific)

This course is intended for maintenance personnel and it will further your knowledge in technical areas of your Salvagnini System. This course will provide you with an understanding of machine communication components, methods, and troubleshooting.

We will start this section with a lesson on what controls the machine components, what the machine looks for, how to directly control certain machine functions, and how to use related Salvagnini software to monitor these actions.

This course will provide:

• Salvagnini Monitor application as a real time dashboard

• CAN BUS system layout, connections, power, theory, and testing.

• Comprehensive lesson on safety components, (Pilz) controls, software, and troubleshooting.

• We will review related pneumatic, electrical, and hydraulic symbols and use Salvagnini software to find related schematics on your machine.

• There will be a dedicated lesson for machine axes drives systems, their software, and troubleshooting.

The next part of the course will focus on the preventative maintenance list of the specific system. We will incorporate the use of the on-board Maintenance Manager application that will aid in keeping track of maintenance items. The Preventative Maintenance chapter will be utilized along with guiding the worker to the indicated point on the system for each item.

This course is limited to one system per course. Make sure to insert the intended system when registering.

This course is available on-site at your facility or in our Hamilton, Ohio Salvagnini America Campus.

Course Length: 3 days

-

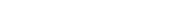

Panel Bender Programming: Fundamentals of Code

Learn the fundamentals of the Salvagnini Panel Bender Technology. This course will focus on the numerical control code to teach you how to create a finished panel for your system. From an open-ended channel to a closed box design, you will gain the fundamental techniques needed to produce a variety of products.

This course will teach you how to write, produce, and adjust a program based on different material properties. Learn the different types of bends aligned with the options on your system.

• Positive and negative bends

• Safety edge bends

• Large radius bends

• Special bending operations with auxiliary tools CLA (if applicable)

• Bend and cut profiles (if applicable)

• Scoring lines (if applicable)

Learn in our Campus with a dedicated terminal per user, and utilize the software to aid in making part programs that are ready to test on your system. Learn on the same software that is available with your system purchase.

• Office Console and Program Editor

• SimulP4

Course Length: 3 days

-

Panel Bender Programming: STREAMBEND

Learn the fundamentals of the Salvagnini Panel Bender Technology. This course will focus on the numerical control code and available software to teach you how to create a program for your P1/P2/P4 system. It will prepare you to take a part design out of CAD and produce a finished panel. From an open-ended channel to a closed box design, you will gain the fundamental techniques needed to produce a variety of products.

This course will teach you how to write, produce, and adjust a program based on different material properties. Learn the different types of bends aligned with the options on your system.

• Positive and negative bends

• Safety edge bends

• Large radius bends

• Special bending operations with auxiliary tools CLA (if applicable)

• Bend and cut profiles (if applicable)

• Scoring lines (if applicable)

Learn in our Campus with a dedicated terminal per user, and utilize the software to aid in making part programs that are ready to test on your system. Learn on the software applications aligned with the options purchased with your system.

• Stream Bend Edit

• Stream Bend Auto

• SimulP4 - Simulator

• Office Console and Program Editor

Learn how to write a single part program that will cover varying sizes and features by converting the program code into parametric code.

• PartS: Application overview and usage description. (If applicable)

• ValueS: Application overview and usage description. (If applicable)

• Solidworks Add-in: Application overview and usage description. (If applicable)

Course Length: 5 days

-

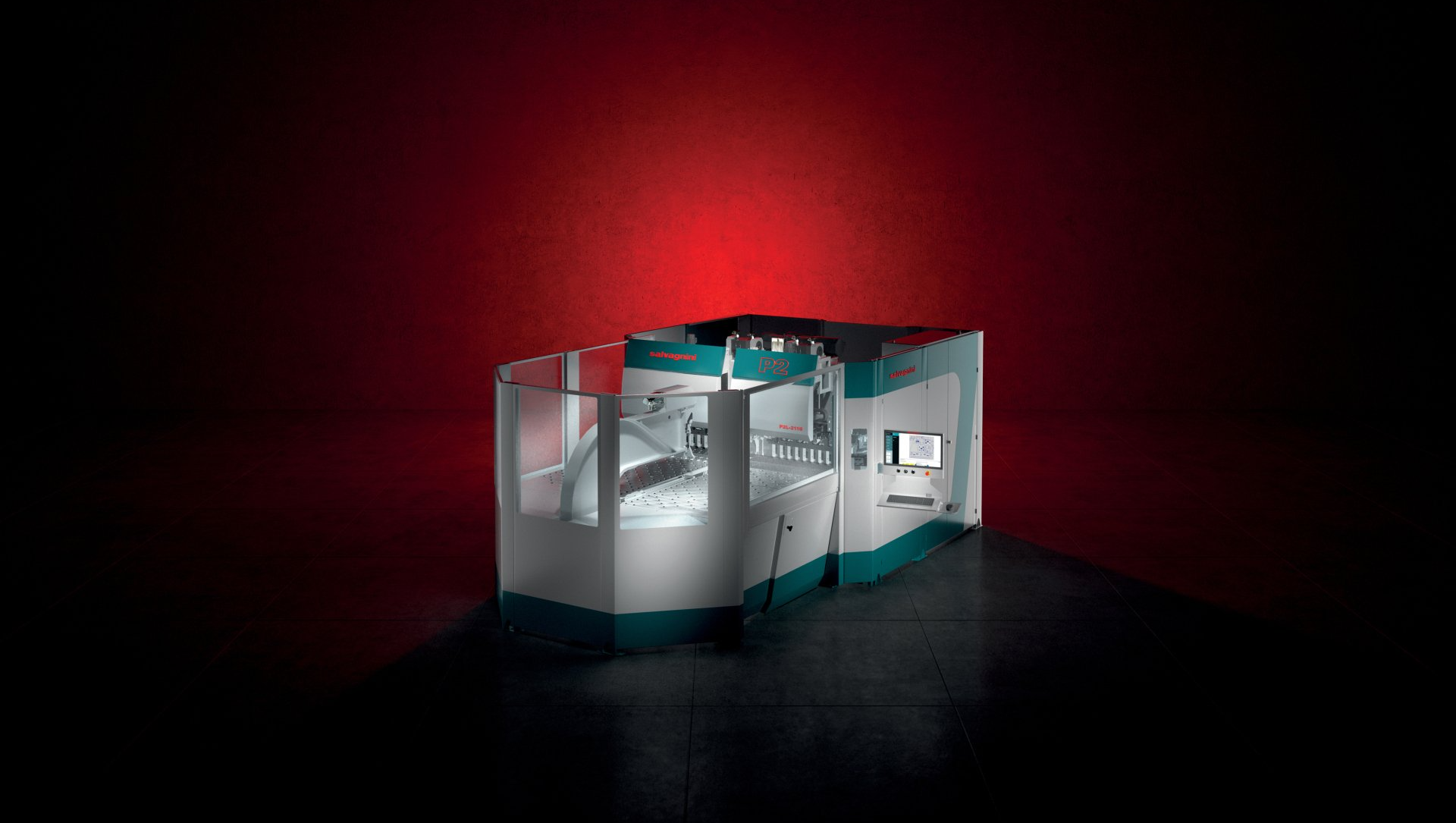

Press Brake Programming: STREAMFORMER

Learn the fundamentals of the Salvagnini B3 Technology. This course will focus on the techniques for off line programming using the available CAM software.

It will teach you how to create a complete program for your Press Brake. It will detail the process of starting with any CAD design through the transfer of the program to the machine.

An emphasis is made on the 3D environment for visualizing the part design which is carried through to the machine console in order to aid the operator.

The lessons are done using your specific machine configuration alternating theory with programming exercises. The exercises are developed gradually based on the required designs, purchased punch and die setups, and other options included in the sold system. A description and explanation of the system, size components like reference system, and angle measurement options will assist in learning the machine capabilities.

• Classification and description of bend types

• Classification and description of tool types: punches, dies, ends, hemming tools

• Classification and description of tool adapters

• Tools database press setup functions

• CAM processing to optimize bend sequence, and back gauge positions

• Learning about various types of tool station set ups

• Automatic, semi-automatic, and manual part process methods

• Batch processing if applicable to your system

Learn in our Campus with a dedicated terminal per user, and utilize the software to aid in making part and nest programs that are ready to test on your system. Learn on the software applications aligned with the options purchased with your system.

• Office Console and Program Editor

• PartS: Application overview and usage description. (If applicable)

• ValueS: Application overview and usage description. (If applicable)

Course Length: 3 days

-

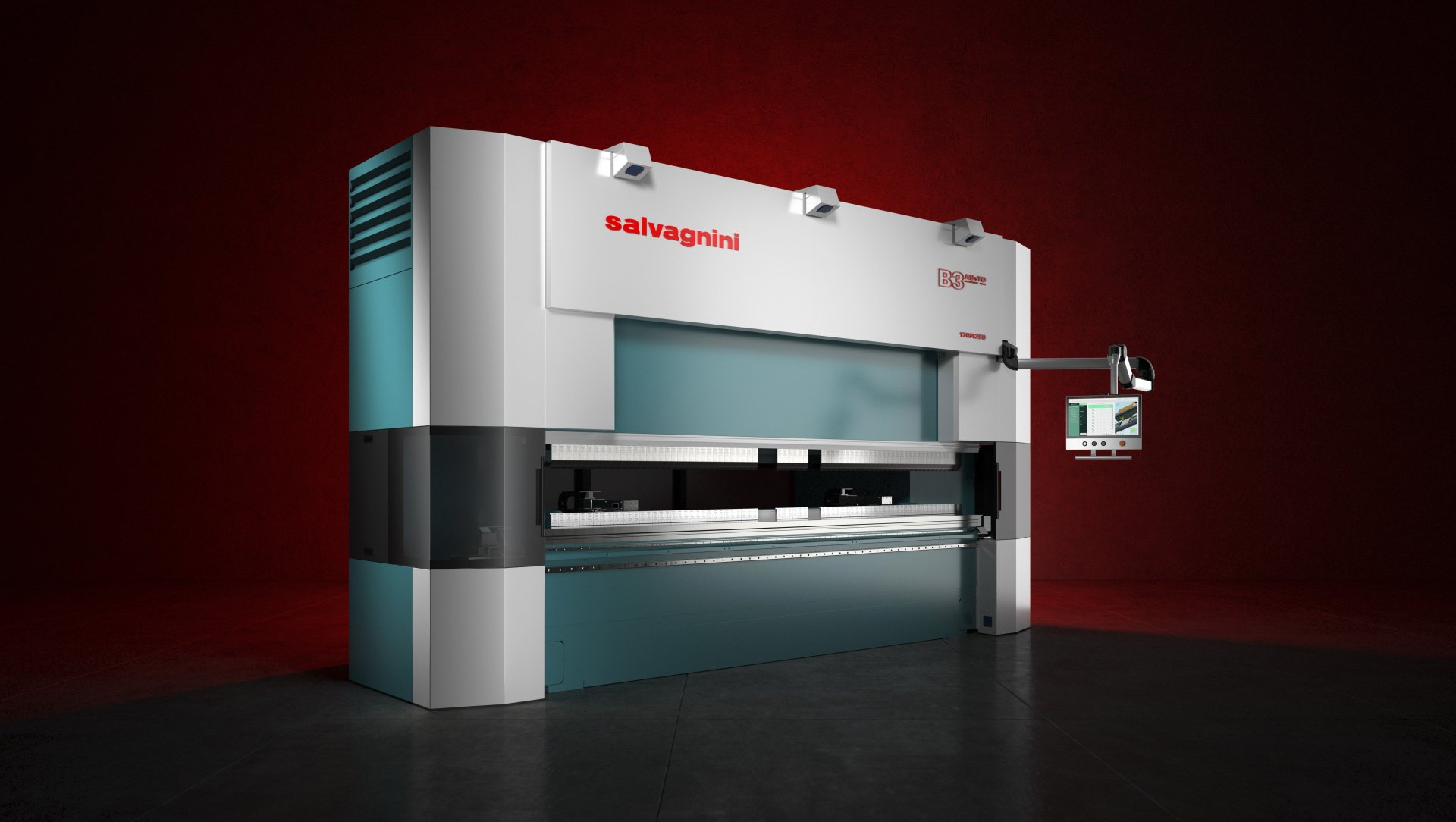

LASER Programming: STREAMLASER

Learn the fundamentals of the Salvagnini LASER Technology. This course will focus on the numerical control code and available CAM software to teach you how to create a complete program for your L3/L5 system. It will prepare you to take a part design out of CAD and produce a flat sheet metal panel ready for further processing or in-line production.

We will also provide the knowledge to optimize production time and minimize residual scrap.

From in-line continuous flow to batch production you will gain the fundamental techniques needed to produce for a variety of production methods.

The lessons are done using your specific machine configuration alternating theory with programming exercises. The exercises are developed gradually based on the required designs, available assist gases and options included in the sold system. A description of the system and explanation of components like the focus head, capacitive sensor, and alignment options will assist in learning the machine capabilities.

• LASER cutting parameters database and its relation to the material database

• Focus position and beam size in relation to limits of material thickness

• LASER reference systems and sheet size limits in feeding and unloading stations

• Use special features like micro-joints, layers management, and etching

• Single program processing with STREAMLASER.

• Nest creation exercises in automatic and manual mode. See the effect of variations in algorithms, clusters, minimum piece counts and filler parts

• Options that modify the use of material like common cut and cutting the skeleton

• Options to aid in optimizing the unloading of parts and potential skeleton.

Learn in our Campus with a dedicated terminal per user, and utilize the software to aid in making part and nest programs that are ready to test on your system. Learn on the software applications aligned with the options purchased with your system.

• Stream LASER CAM

• ToolShell

• SimFiber - simulator

• Office Console and Program Editor

• PartS: Application overview and usage description. (If applicable)

• ValueS: Application overview and usage description. (If applicable)

• Solidworks Add-in: Application overview and usage description. (If applicable)

Course Length: 4 days

-

Punching | LASER Programming: STREAMPUNCH EVO

Learn the fundamentals of the Salvagnini Punch and Fiber LASER Technology. This course will focus on the numerical control code and available CAM software to teach you how to create a program for your S1 system.

It will prepare you to take a part design out of CAD and produce a flat sheet metal panel ready for further processing or in line production. We will also provide the knowledge to optimize production time and scrap management.

From in line continuous flow to batch production you will gain the fundamental techniques needed to produce for a variety of production needs. The lessons are done using your specific machine configuration alternating theory with programming exercises. The exercises are developed gradually based on the required designs, purchased punches and options included in the sold system.

The machine reference system and structure of the punch tool database is covered in order to teach the programmer how to create a head set-up.

• Multi-press head analysis and its configuration options. Work limits as a function of punch position.

• S1 reference systems and sheet size limits in feeding and unloading stations

• Use of DBHT data base of tool shapes including special punches

• Fiber LASER cutting parameters database and limitations on material thicknesses

• Single program processing with STREAMPUNCH.

• Nest creation exercises in automatic and manual mode. See the effect of variations in batch sizes, minimum piece counts and filler parts

• Options that modify the use of tools, nesting algorithms, and machine cycles

Learn in our Campus with a dedicated terminal per user, and utilize the software to aid in making part and nest programs that are ready to test on your system. Learn on the software applications aligned with the options purchased with your system.

• Stream Punch Evo CAM and material database

• DBHT tools database

• SimPunchS1 - Simulator

• Office Console and Program Editor

• PartS: Application overview and usage description. (If applicable)

• ValueS: Application overview and usage description. (If applicable)

• Solidworks Add-in: Application overview and usage description. (If applicable)

Course Length: 5 days

-

Punching / Shear Programming: STREAMPUNCH

Learn the fundamentals of the Salvagnini Punch/Shear Technology. This course will focus on the numerical control code and available CAM software to teach you how to create a program for your S4/S2 system.

It will prepare you to take a part design out of CAD and produce a flat sheet metal panel ready for further processing or in line production. We will also provide the knowledge to optimize production time and minimize residual scrap.

From in line continuous flow to batch production you will gain the fundamental techniques needed to produce for a variety of production needs.

The lessons are done using your specific machine configuration alternating theory with programming exercises. The exercises are developed gradually based on the required designs, purchased punches and options included in the sold system. The machine reference system and structure of the punch tool database is covered in order to teach the programmer how to create a head set-up.

• Multi-press head analysis and its configuration options. Work limits as a function of punch position.

• S4 reference systems and sheet size limits in feeding and unloading stations

• Use of DBHT data base of tool shapes including special punches

• Single program processing with STREAMPUNCH.

• Nest creation exercises in automatic and manual mode. See the effect of variations in batch sizes, minimum piece counts and filler parts

• Options that modify the use of tools, nesting algorithms, and machine cycles

Learn in our Campus with a dedicated terminal per user, and utilize the software to aid in making part and nest programs that are ready to test on your system. Learn on the software applications aligned with the options purchased with your system.

• Stream Punch CAM and material database

• DBHT tools database

• Simul-X - Simulator

• Office Console and Program Editor

Learn how to write a single part program that will cover varying sizes and features by converting the program code into parametric code.

• PartS: Application overview and usage description. (If applicable)

• ValueS: Application overview and usage description. (If applicable)

• Solidworks Add-in: Application overview and usage description. (If applicable)

Course Length: 5 days

Have a question about Salvagnini Training?

Reach out today!

Have a question? We’re here to help.

Send us a message and we’ll get be in touch.

We will get back to you as soon as possible

Please try again later

salvagnini america inc.

27 Bicentennial Court

Hamilton, Ohio 45015 USA

513-874-8284

info@salvagnini.com

Salvagnini America Inc,