DIGITAL JOB SHOPS

Rapid industrial developments of recent years continue to set tough challenges. Because industry has changed: flexibility and efficiency are crucial requirements for managing increasingly smaller batches or rapid item turnover rates. And this scenario is even more common in the job shop sector.

Digital Job Shops

It is not only a matter of the highly volatile production mix: the need to maximize sheet metal use, regain production capacity on bending machines – often not available because of frequent re-tooling or waiting for parts to bend – and reduce WIP machining, are just some of the challenges faced by subcontractors every day. And it is precisely these challenges that are driving subcontractors to choose integrated solutions for process efficiency, capable of applying intelligence to all value-creating activities and minimizing or indeed eliminating all those with low added value.

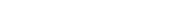

Salvagnini has been concretely tackling this issue since 1993, when it launched the first OPS, the modular software for managing production. OPS receives the production list from the factory information management system in real time, and delivers an updated version to the programmer. It provides support for the programmer's activities by defining priorities, automatically generating the machine programs and sending them to the workshop. It checks the availability of raw materials or semi-finished parts and generates feedback to the factory information management system, updating it in real time, part by part. It can make autonomous decisions according to a production logic – or according to a multiple mix of production logics – designed to meet the needs of the customer and transformed into an algorithm. It integrates labeling, traceability and store-tower management upstream and downstream of the cutting, punching and bending activities. However, to understand how OPS really improves each step in the process, we need to isolate it and consider it separately.

SIGN UP TODAY TO STAY IN THE KNOW OF EVERYTHING THAT SALVAGNINI HAS TO OFFER

Rapid industrial developments of recent years continue to set tough challenges.

Because industry has changed: flexibility and efficiency are crucial requirements for managing increasingly smaller batches, rapid item turnover rate and tight lead times.

We will get back to you as soon as possible

Please try again later

Upstream from the workshop: increasing programming efficiency

Generally, it is the management software – ERP, MRP – that starts every activity by generating a production list. Very often this is a static, paper list, which is then transferred manually to the CAD/CAM programming. Here, the programmer organizes production, manually analyzing the production orders, pairing the part codes with the related machine programs, rationalizing the programming demands according to urgency, type of material or format. Although fundamental, these are very burdensome activities with low added value, which impact waiting times and have a potential risk of error. In contexts with high item turnover rates and extremely small batch sizes, this is where production bottlenecks may well lie.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

By adopting OPS, during programming, it is possible to:

• automatically create punching/cutting nests;

• group parts together according to type of material, thickness, bending technology and tool set-up needed for production;

• manage production intelligently, considering priorities and available sorting areas;

• reduce or eliminate all activities with low added value, redundant activities and any unnecessary functions and operators;

• ensure real-time visibility of production orders.

One extremely relevant case study in this sense comes from Tecnolaser, a leading subcontractor in Veneto, Italy. To reduce total programming times by at least 50%, in 2014 Tecnolaser launched a digitalization project to optimize programming and order management. A value flow analysis highlighted that it took between 4 and 5 days for around 6 actual hours of work – from order receipt and data entry to programming, nesting and sending the programs to the machinery. The implementation of OPS brought some amazing results: the average time needed to manage an order and deliver the programs to the machine fell from 5 days to around 2 hours – a 95% reduction. But the most interesting effect was the elimination of the risk of error: automatically transferring information allowed Tecnolaser to take a huge step forward.

Increasing punching and cutting efficiency

Once the programming issue has been solved, however, other problems can frequently occur. Paper production lists have limits: on the one hand they are static and inflexible, and on the other they offer no visibility of what has actually been produced. The problem can only be resolved if the operator provides manual feedback after completing each production list – a limit in a market characterized by increasingly short times, where production for stock is a thing of the past: the feedback often arrives too late, when it is no longer possible to remedy any delays, and ends up by creating urgencies. And the operator is the one who pays the price of the high production variability required to manage these urgencies.

Using OPS in the punching and cutting phase helps to:

- organize the operator’s work clearly without compromising on flexibility, managing urgent jobs and changing the production list in real time;

- ensure real-time visibility of the state of progress of production orders;

- regain efficiency and reduce waiting times, by improving programming activities.

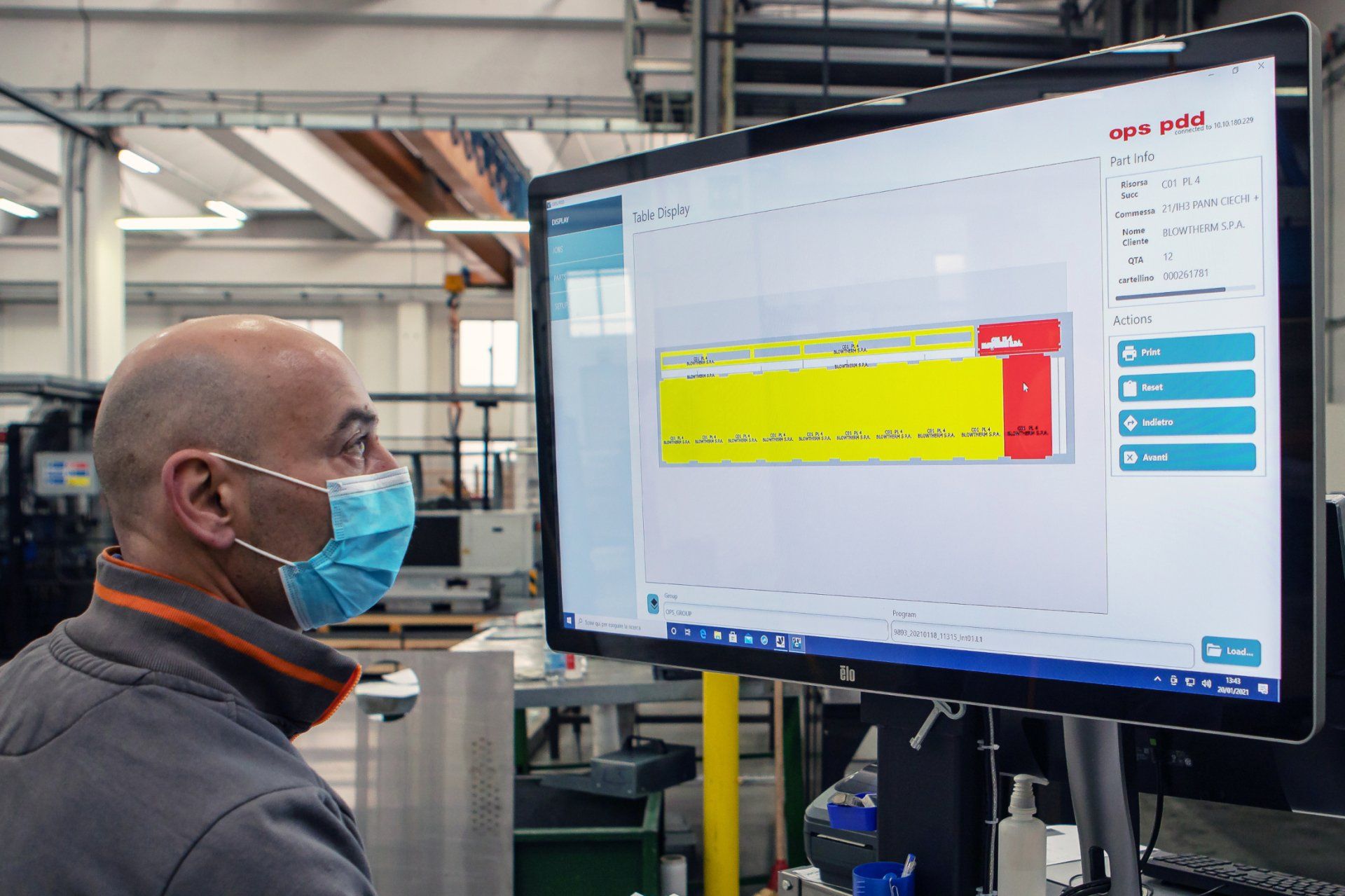

Sorting and storing semi-finished parts: increasing the efficiency of low-added-value activities

Sorting and storing semi-finished parts are separate phases of the production process. They are necessary activities but generate no value for the customer. When managed conventionally, separation and stacking are complex activities.

Often the nest drawing, printed on paper, is the only information available to the operator for physically recognizing the parts, sorting them and assigning them to the store or to machining stations downstream. Equally often, with geometrically similar parts, the operator is forced to use measuring instruments to be absolutely sure of identifying the part.

Using OPS in the sorting and storage phase helps to:

- guide the operators through all activities, minimizing waiting times and the risk of error;

- advantageously organize the semi-finished part for subsequent machining, thus recovering efficiency;

- accurately identify and track the parts;

- facilitate a just-in-time approach to subsequent machining, as it is the actual availability of the parts in the store that launches production on the bending machines.

From this point of view, the project for the Veneto-based subcontractor ESSE4 is significant. Thanks to OPS, when installing a new P2lean panel bender, Salvagnini digitalized the management of the semi-finished part store, located between the cutting and bending departments. All WIP parts are manually placed on specific pallets by the operators, in unambiguous positions coded with barcodes. When handling the parts – for internal logistics or for a matter of space – the operators update the code position, with no errors or waiting times.

“The semi-finished part store is a buffer that guarantees rapid order management, but has always been complex to manage,” one of the owners explains. “Today, digitalization has allowed us to fully exploit the reactivity of our panel benders: the availability and traceability of the semi-finished part allows us to respond just in time to the requests, with extremely short lead-times, that some of our major customers make.”

Bending efficiency can also be increased

Salvagnini has been sensitive to the topic of bending efficiency since 1977, the year in which Guido Salvagnini designed and produced the first P4 panel bender. Over the years, Salvagnini panel benders have never stopped evolving, and today are flexible production solutions that do not require re-tooling and that automatically adapt to the size of the part to be produced, in-cycle, without machine stops or manual re-tooling. Today Salvagnini press brakes work with the same vision too, thanks to a wide range of devices that extend their autonomy and flexibility.

With such high-performing systems, we have to look at the process in order to regain even more efficiency. The advantages guaranteed by OPS in the bending phase are indeed process-related, as it is here that we can see the results of the work done in the previous phases. The dynamic production list can faultlessly manage urgencies and surprises, while part traceability allows the operators to identify them quickly and safety, eliminating waiting times and errors.

In short, by adopting OPS during the bending phase, it is possible to:

- organize the operator’s work clearly without compromising on flexibility, managing urgent jobs and changing the production list in real time;

- guide the operators through all activities, minimizing the risk of error and unnecessary re-tooling;

- reduce waiting times, by improving sorting and storage activities, and offering the possibility of rapidly identifying the semi-finished part to use;

- fully exploit the production capacity of panel benders and press brakes;

- ensure real-time visibility of the state of progress of production orders.

The project implemented at ESSE4 is particularly interesting from this point of view too. On the basis of the orders received from the company ERP, OPS checks if there are any components ready for bending in store, processes the information and issues the production jobs to be sent to the press brakes or panel benders. OPS makes the production list available and guides the operator on a simple graphic interface installed on all the machines. But OPS also balances the load of each machine, according to the order and the parts to be machined. This is an added value which further optimizes throughput times.

“The new approach has led to a new 4.0 method, which we have extended to the whole machine inventory,” one of the owners continues. “On the older ones, Salvagnini is performing an impressive program of retrofitting and adaptation to specific requests for digital interconnection.”

A perfect solution for the 4.0 subcontractor

The driver of new investments seems an obvious equation: to increase productivity, we have to buy new systems. Salvagnini proposes to replace this purely quantitative aspect with another that combines both quantity and quality, shifting from the idea of production capacity to that of production control, where efficiency – and therefore productivity - can be regained.

“There is no point insisting on extremely high-performing technologies without managing the bottlenecks upstream and downstream of production,” states Stefano Cera, Salvagnini Product Manager for software. “This means that it is pointless to focus on reducing the cutting times of a nest by a few percent if the automation devices cannot guarantee sorting at the same level, if the operators aren’t able to separate the parts in the times set or, even more frequently, if the semi-finished part store is a black hole that sucks up huge amounts of efficiency. In the same way, this means that it is pointless to focus on reducing part bending cycles by a few seconds if it isn’t possible to identify the semi-finished parts to be bent in the store or feed the machine in the right times because the operator is busy doing something else. For Salvagnini, that’s what digitalization is all about: making available solutions that are easy to use, in order to focus on control, production process optimization and the elimination of all those often invisible down times that undermine the efficiency and competitive performance of companies. We think this support is fundamental for managing complex, dynamic productions in today’s industrial scenario, with increasingly smaller batches, high item turnover rates, tight lead-times and urgencies.”

CONTACT US

Leave us your info and we will get back to you.

Contact Us

We will get back to you as soon as possible

Please try again later

Check out our additional articles!

-

AVS

LEARN MORE ABOUT AVSAll the benefits of artificial vision

-

GOING GREEN

LEARN MORE ABOUT GREEN TECHNOLOGYPanel bending is green at last, with Salvagnini

-

Flexible Automation

Learn more about Flexible AutomationAutomation according to Salvagnini

-

Digital Jobshops

LEARN MORE ABOUT JOBSHOPSUpstream from the workshop: increasing programming efficiency

salvagnini america inc.

27 Bicentennial Court

Hamilton, Ohio 45015 USA

513-874-8284

info@salvagnini.com

Salvagnini America Inc,