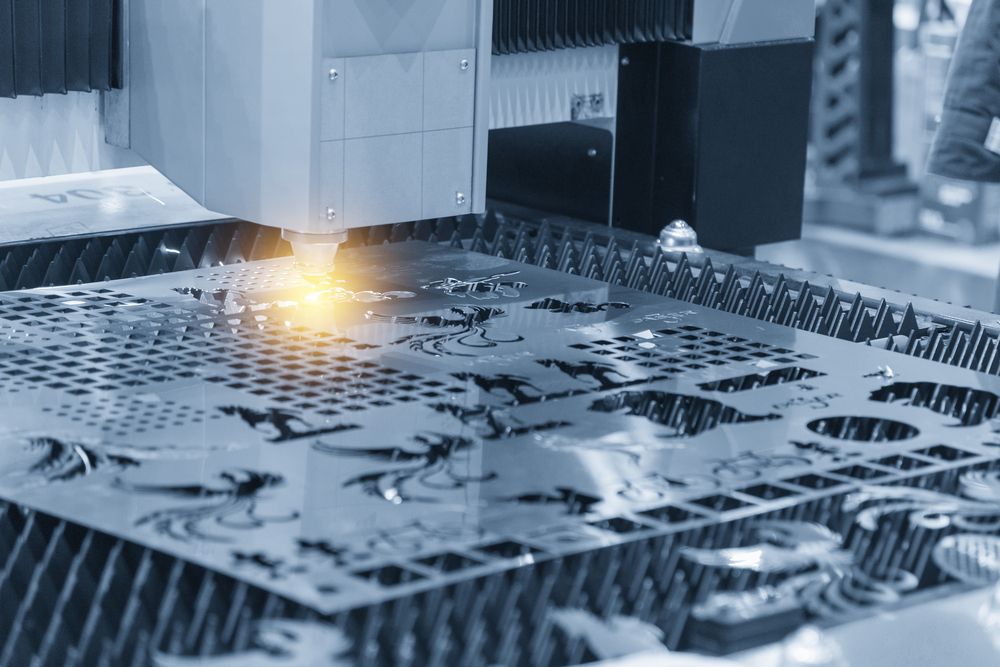

The Role of Robotics in Sheet Metal Fabrication Automation

The sheet metal fabrication industry has seen tremendous growth in recent years, thanks in large part to the adoption of automation technologies like robotics. Robotics and other automated systems have revolutionized the way sheet metal parts are manufactured, making the process faster, more efficient, and more accurate. Let’s explore the role of robotics in sheet metal fabrication automation and how Salvagnini America is at the forefront of this exciting trend!

The Advantages of Robotics in Sheet Metal Fabrication

Robotic automation has several advantages in sheet metal fabrication, including:

- Increased speed: Robots can perform tasks faster than humans, leading to higher productivity and shorter lead times.

- Improved accuracy: Robots can make precise cuts and bends with consistent accuracy, reducing the risk of errors and material waste.

- Cost savings: Robotics can reduce labor costs and minimize material waste, leading to significant cost savings over time.

- Flexibility: Robots can be programmed to handle a wide range of sheet metal parts, making them a versatile option for sheet metal fabrication.

At Salvagnini America, we offer a wide range of robotic automation products that can perform a variety of sheet metal fabrication tasks with speed and precision, from cutting and bending to punching and forming.

The Benefits of Artificial Intelligence in Sheet Metal Fabrication

Artificial intelligence (AI) is another technology that is making waves in the sheet metal fabrication industry. By using machine learning algorithms and data analysis, AI can help improve the efficiency and accuracy of fabrication processes. Some benefits of AI in sheet metal fabrication include:

- Predictive maintenance: AI can monitor machines and identify potential issues before they cause downtime, reducing the risk of costly repairs and delays.

- Quality control: AI can analyze data from production processes to identify trends and patterns, allowing for continuous improvement and higher-quality products.

- Optimization: By analyzing data and identifying areas for improvement, AI can help optimize processes for maximum efficiency and cost savings.

At Salvagnini America, we are constantly incorporating new AI technologies into our machines to improve performance and efficiency. For example, our latest machines use AI to optimize the sheet metal nesting process, reducing material waste and improving productivity. Contact our Sales team to discover how Salvagnini America machines can help your organization!

The Future of Robotics and AI in Sheet Metal Fabrication

As the sheet metal fabrication industry continues to evolve, it is clear that robotics and AI will play an increasingly important role in the automation process. Some of the trends we expect to see in the future include:

- Collaborative robots: Collaborative robots, or cobots, are robots designed to work alongside humans. These machines are ideal for tasks that require human input or judgment, such as assembly or quality control.

- Advanced sensors: Advanced sensors can be used to monitor machines and production processes, providing real-time data that can be used to optimize performance and reduce downtime.

- Predictive analytics: Predictive analytics uses data analysis and machine learning to predict future events, such as machine failures or production delays. By identifying potential issues before they occur, predictive analytics can help reduce downtime and improve overall efficiency.

At Salvagnini America, we are committed to staying at the forefront of these trends, constantly researching and developing new automation technologies to improve the performance and efficiency of our machines.

Automation and AI are transforming the sheet metal fabrication industry, improving efficiency, accuracy, and productivity. At Salvagnini America, we are committed to incorporating these, and more, technologies into our machines to provide our customers with the most advanced and reliable sheet metal fabrication machinery available. If you are looking to take your sheet metal fabrication operations to the next level,

contact us today to learn more about our range of automated and AI-enabled machines.

salvagnini america inc.

27 Bicentennial Court

Hamilton, Ohio 45015 USA

513-874-8284

info@salvagnini.com

Salvagnini America Inc,