Industrial Technology Explained

Whether you're a doctor, engineer, manager, HR, or student—pretty much anybody living in the 21st century must understand what industrial revolution 4.0 means. More than ever, digital technology became the distinguishing factor during the COVID-19 pandemic period, and people realized how important technology is. With restricted movements, the world resorted to technology for online shopping, online teaching, remote working, virtual exhibitions, and events using digital platforms.

These technological advancements have a direct impact on the industrial revolution. An industrial revolution refers to major changes and transitions in manufacturing and industrial processes with new and innovative technologies.

What Is Industrial Technology?

Industrial technology uses manufacturing and engineering technology to make production faster, simpler, and more efficient. This field of study is devoted to improving industrial processes' productivity, profitability, and safety through engineering and manufacturing technology.

Industrial technology heavily relies on a technically efficient and creative workforce to help a company realize efficiency and profitable productivity.

The programs in this field typically include instructions and optimization theory, human factors, organizational behavior, industrial processes, industrial planning procedures, computer applications, and report and presentation preparations.

To become an industrial technologist, you need to be an expert in planning and designing manufacturing processes and equipment. The role involves being responsible for implementing specific designs and processes to help improve performance.

Industrial technology involves managing, operating, and maintaining complex operations systems.

Industrial Technology in the Manufacturing Industry

The manufacturing industry has been revolutionized through monumental industrial and technological phases. Here are highlights of the groundbreaking technological advancements that have occurred through time.

- Industrial revolution 1.0 (1784)- Using machines powered by water and steam.

- Industrial revolution 2.0 (1870)- Mass production of electricity and steel

- Industrial revolution 3.0 (1969)- Introduction of electronics, automation, and computers

- Industrial revolution 4.0 (today)- A cyber-physical system guides it. It connects the real world with the virtual world.

The industry's workforce includes automated processes and people. It continually strives to improve productivity and efficiency by employing the best mediums to help manage its workforce.

For a sector that dictates consumer behavior, the manufacturing industry continually invests in comprehensive education to empower its personnel with the best technical and leadership skills. It's imperative that this industry reduces the cost of production by minimizing resource constraints on time, budget, and resources.

What Is Manufacturing Technology?

It refers to the processes and techniques used to improve manufacturing practices, quality, and productivity.

Manufacturing technology also refers to modern scientific and engineering methods used in industrial production and manufacturing processes.

These technological innovations directly drive ROI. Here are some of the benefits you stand to gain.

- Predictive and proactive maintenance

- Operational flexibility

- Safety working options

- Increased innovation

What Does Manufacturing Technology Include?

It includes industry 4.0 relevant technology that helps in automation, digital technology, the Internet of Things, artificial intelligence, machine learning, and data exchange. The current manufacturing technology is so advanced that it can only pass as science fiction if we looked back at its state about two decades ago.

Manufacturing technology has led to powerful and unprecedented breakthroughs in:

- Quality control

- Inventory management

- Shop floor management

- Worker training

- Manufacturing software and equipment

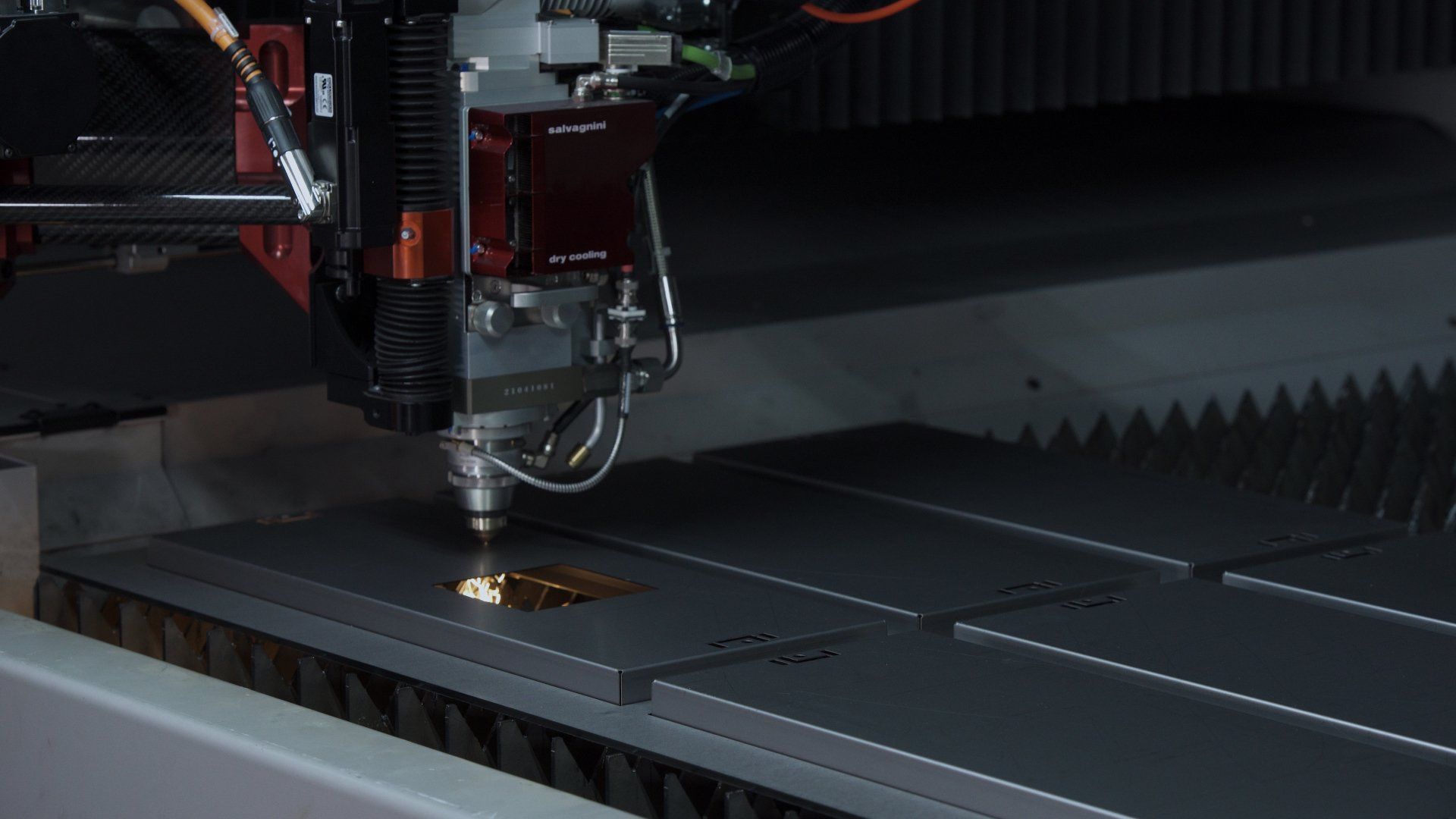

Why Choosing Salvagnini America for Your Fabrication Needs Is a Good Choice

Do you want to optimize technology to help you reduce production expenses and manage your team better? Salvagnini America can help!

We provide the latest technologies for punching, laser cutting, bending, and the automation that turns operations into processing systems for sheet metal manufacturing companies. Its software suite includes CAD/CAM software, CAM optimization, assembly management, inspection and reporting, and more. With this technology, you can make changes to designs and then test those changes before actually producing the part.

We want to help you gain the profound knowledge needed to maximize productivity using cyber-physical systems (CPS), digital technologies, and a collaboration of all aspects of the productive process, i.e. operators and machines.

We are located in North America, Ohio, and have successfully done sheet metal installations in 160+ application sectors. Salvagnini America has served over 75 countries and witnessed industrial and technological advancements for over four decades.

Contact us today to help take your business to a technologically powered level.

salvagnini america inc.

27 Bicentennial Court

Hamilton, Ohio 45015 USA

513-874-8284

info@salvagnini.com

Salvagnini America Inc,