How Automation Improves the Accuracy and Consistency of Sheet Metal Fabrication

In the world of sheet meta fabrication,

precision and consistency are non-negotiable. The tiniest deviation from specifications can spell disaster, resulting in costly errors, project delays, and dissatisfied clients. However, thanks to the ongoing revolution in automation technology, manufacturers and job shops can now achieve unprecedented levels of accuracy and consistency. Leading the charge on this industry transformation is Salvagnini America. Let's explore how automation, in conjunction with Salvagnini's cutting-edge products and software components, can significantly enhance the precision and consistency of sheet metal fabrication processes.

The Role of Automation in Sheet Metal Fabrication

Automation in sheet metal fabrication represents the deployment of advanced machinery and computer-controlled systems to perform tasks that were once reliant on manual labor. This transformative approach optimizes the production process by minimizing the potential for human error and ensuring consistent quality across all fabrication components. Salvagnini has consistently been at the forefront of this transformation, developing innovative solutions that streamline manufacturing operations.

P4 Automatic Panel Bender

Salvagnini's P4 Automatic Panel Bender is a revolutionary machine in the world of sheet metal bending. This state-of-the-art device automates the bending process with unrivaled precision. Equipped with advanced sensors and cutting-edge software, the P4 can meticulously measure and adjust each bend, guaranteeing the formation of even the most complex shapes with pinpoint accuracy and uniformity. This level of automation dramatically reduces the possibility of errors that might creep in during manual bending, such as variation in angles and dimensions.

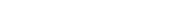

Fiber Laser Cutting Systems

Salvagnini's fiber laser cutting systems are celebrated for their speed and precision. These machines employ high-powered lasers to cut sheet metal with remarkable accuracy. The built-in automation features in these systems ensure that every cut adheres meticulously to the programmed design, eliminating human error and delivering consistent results, even in high-volume production environments.

Salvagnini's Exceptional Software Solutions

Salvagnini doesn't stop at hardware innovations; they also provide cutting-edge software solutions that seamlessly integrate with their machinery to further enhance the accuracy and consistency. The Salvagnini software suite encompasses CAD/CAM integration, real-time monitoring, and production optimization tools. These software components empower fabricators to design, stimulate, and oversee the entire production process from a unified interface, reducing the likelihood of errors and ensuring that each part is manufactured with unwavering adherence to specifications.

Quality Assurance and Traceability

One of the pivotal advantages of using Salvagnini's automation solutions is the ability to uphold stringent quality control and traceability throughout the production process. Salvagnini's software components facilitate real-time monitoring of production parameters and quality checks. This means that any deviations from specifications can be promptly identified and rectified, minimizing waste and rework. Furthermore, the traceability features enable manufacturers to trace the history of each part, ensuring accountability and compliance with industry standards.

In the word of sheet metal fabrication, precision and consistency are not just goals; they are prerequisites for success. Salvagnini America stands as a trailblazer in delivering automation solutions that not only enhance precision and consistency but also elevate productivity and efficiency. With cutting-edge products like the P4 and laster cutting systems like the L3 and L5, complemented by advanced software components, manufacturers can confidently rely on their sheet metal components adhering to the strictest quality standards.

As technology continues to advance, Salvagnini remains dedicated to pushing the boundaries of what's achievable in sheet metal fabrication. By embracing automation and harnessing Salvagnini's groundbreaking solutions, fabricators can enjoy the peace of mind that comes with knowing their products will be fabricated with the utmost precision and consistency. This translates to heightened customer satisfaction and a competitive edge in the industry, which are essential in today's fast-paced and demanding manufacturing landscape.

Get in touch with the Salvagnini America sales team today to discuss how our automation options can benefit your production business!

salvagnini america inc.

27 Bicentennial Court

Hamilton, Ohio 45015 USA

513-874-8284

info@salvagnini.com

Salvagnini America Inc,